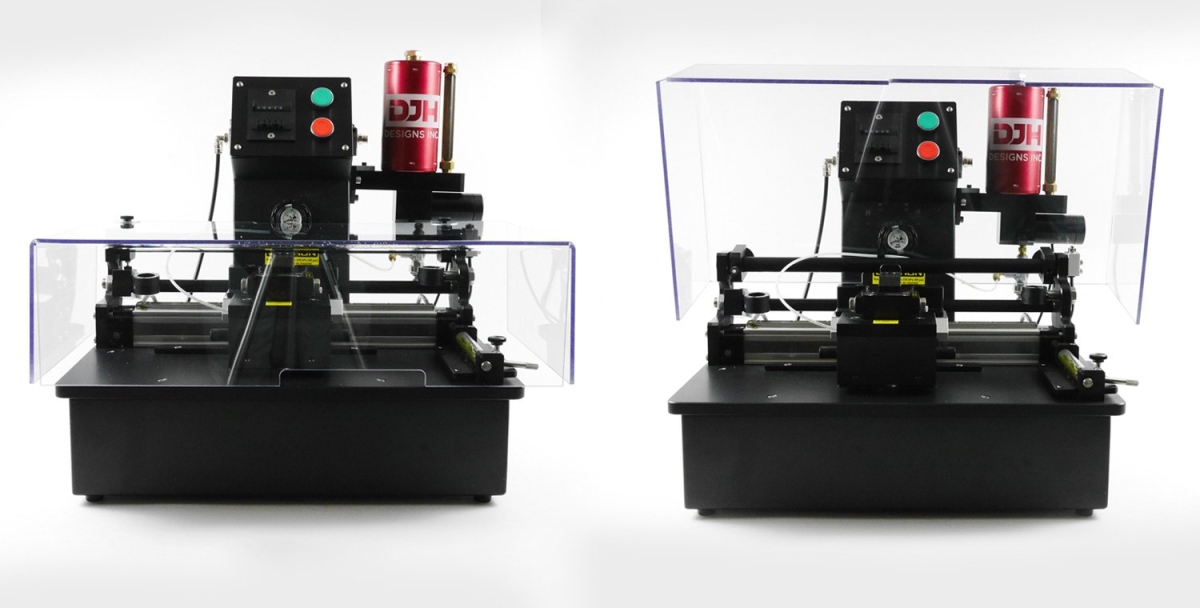

DJH - Mek Rub Test Machine

Quantity

Features and Benefits

Specifications

- Easy to setup, simple to operate

- Repeatable consistent results, constant pressure dead weight rubbing block

- Front panel mounted controls

- Minimal solvent usage, adjustable solvent flow metering valve

- 425cc solvent reservoir with auto shutoff control

- Quick Change solvent pad system

- Controlled Stroke count, counter can be set from 1 to 9999 strokes

- CE Certified

- Intrinsically safe – no electrics, all pneumatic operation.

- Minimized operator contact with and exposure to Solvent

Specifications

| WEIGHT OF MACHINE | 28.3 kg (62.5 lbs) |

| MEK RESERVOIR CAPACITY | 425 cc |

| MASS OF RUBBING BLOCK | ASTM Standard 3kg (6.8 lbs) / EU Standards 1000g |

| STROKE LENGTH | 203mm (8”) |

| NUMBER OF STROKES/MIN (DOUBLE RUB) | 70 |

| OPERATIONAL AIR PRESSURE | 550 KPa (80 psi) |

| MAX AIR SUPPLY PRESSURE | 965 KPa (140 psi) |

| AIR CONSUMPTION @ OPERATIONAL PRESSURE | 2.35 SCFM @ 550 KPa (80 psi) |

| MINIMUM FLEXIBLE AIR LINE SUPPLY SIZE | ¼” I.D. |

| AIR INLET CONNECTION AT FILTER | ¼ NPT |

| COTTON PAD SIZE | 1½ x 1¾, 2 ply |

| COUNTER MIN/MAX NUMBER OF STROKES | 1-9999 |

| AIR SUPPLY | 550 kpa (80 psi) Clean and dry (non condensing) |

| DIMENSIONS (WIDTH DEPTH HEIGHT) | 457x483x483mm (18”x19”x19”) |

| TEST PANEL SIZE | 127mm x 305mm (5” x 12”) |

| ELECTRICAL REQUIREMENTS | None (all pneumatic system) |

| PANEL THICKNESS MAX** | 3.2 mm (1/8”) **thicker panels can be run with a simple adjustment. |