TQC sheen - Bending / Impact / Cupping Testers - Automatic Cupping Test

Quantity

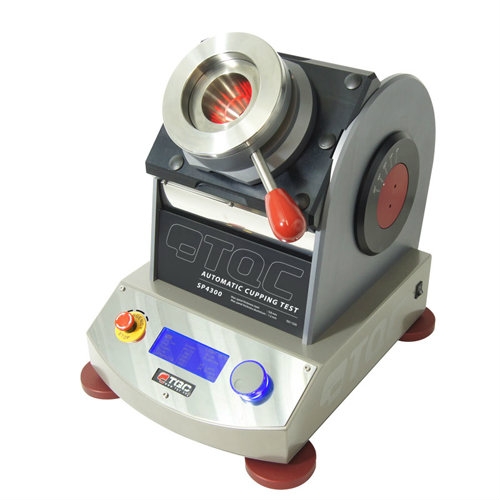

TQC Automatic Cupping Tester to perform a cupping (Erichsen / Dent) test on coated steel panels to define the resistance of paint, varnish or related products to cracking and/or detachment from a metal substrate when subjected to gradual deformation by indentation under standard conditions.

The test is either used as a “pass / fail” test by testing to a specified depth or defining the minimum depth at which a coating fails by gradually increasing the indentation.

The ISO 1520 standard requires panels to be slowly deformed at a steady rate between 0,1 mm/s and 0,3 mm/s without interruption. Especially with thicker steel panels hand-operated testers not always allow an uninterrupted deformation.

The TQC Automatic Cupping Tester is driven by a micro-step controlled electro motor which allows precise and steady deformation with 0,01 mm steps. Operation is intuitive by means of a jog-dial switch and a multi-lingual operating menu on a large illuminated display.

An integrated LED powered sample illumination system comforts examining the coating under test. To guarantee maximum visibility of all possible types of surface including high gloss, matte or colored samples the angle of the LED light can be set. Choose light from just one or all directions. The strength of the LED’s is adjustable but also the colors can be changed to achieve maximum contrast.

Mandatory test in Qualicoat and QIB accredited laboratories.

Standards

EN-ISO 1520, DIN 53156, DIN 53232, BS 3900-E4, NBN T22-104, NFT 30 019. Look up the appropriate standard for a correct execution of the test.

Features

ORDERING INFORMATION

Art. No. SP4300

TQC Automatic Cupping Test 230VAC / 50Hz

Art. No. SP4305

TQC Automatic Cupping Test 110VAC / 50/60Hz

The test is either used as a “pass / fail” test by testing to a specified depth or defining the minimum depth at which a coating fails by gradually increasing the indentation.

The ISO 1520 standard requires panels to be slowly deformed at a steady rate between 0,1 mm/s and 0,3 mm/s without interruption. Especially with thicker steel panels hand-operated testers not always allow an uninterrupted deformation.

The TQC Automatic Cupping Tester is driven by a micro-step controlled electro motor which allows precise and steady deformation with 0,01 mm steps. Operation is intuitive by means of a jog-dial switch and a multi-lingual operating menu on a large illuminated display.

An integrated LED powered sample illumination system comforts examining the coating under test. To guarantee maximum visibility of all possible types of surface including high gloss, matte or colored samples the angle of the LED light can be set. Choose light from just one or all directions. The strength of the LED’s is adjustable but also the colors can be changed to achieve maximum contrast.

Mandatory test in Qualicoat and QIB accredited laboratories.

Standards

EN-ISO 1520, DIN 53156, DIN 53232, BS 3900-E4, NBN T22-104, NFT 30 019. Look up the appropriate standard for a correct execution of the test.

Features

- easy-to-use

- user calibration possible

- integrated multi colour led lighting

- Manual and preset mode

- Multiple languages

- Panel holder adjustable in angle

| Indenter Speed | 0.01 – 0.70 mm/s |

| Stroke length | 0-12mm |

| Max panel width | Max 100mm |

| Max. panel thickness steel | Max. 0.8mm |

| Max. panel thickness aluminum | Max. 1.2mm |

| Max. indentation force | 35kN(3500kg) |

| Dimensions(L*W*H) | 450mm * 350mm * 600mm |

| Net weight | Approx. 31 kg |

| Power supply | 115 – 230 V, 50 – 60 Hz |

| Power consumption | Max. 80 Watt |

| Display | Blue illuminated, graphic 100 * 35mm, 193 * 64 pixels |

| Safety | Emergency button, integrated acoustic alarm |

| Function | Jog shuttle knob by rotation/pushing |

| Indenter speed accuracy | +/- 1% of set speed |

| Stroke length accuracy | +/- 0.01 mm or 0.2% whichever is greater |

ORDERING INFORMATION

Art. No. SP4300

TQC Automatic Cupping Test 230VAC / 50Hz

Art. No. SP4305

TQC Automatic Cupping Test 110VAC / 50/60Hz